Jip van den Broek is proud to be the 3rd generation to work at the hatchery in Afferden (L.). In cooperation with Pluriton, Van den Broek runs the hatchery where 350,000 hens are hatched each week. With Pluriton’s own trucks, the chicks are safely on their way to the rearing farms in the Netherlands and abroad after hatching.

In Jip van den Broek’s family business, his parents, who moved the hatchery to Afferden in 1978, still actively work in the hatchery. Father Joop can be found daily in the hatchery and still occasionally drives the truck. Mother Riet helps with hands-on work on and around the hatchery. Sister Janneke has also been working in the business for a year, manning the front desk. With great passion and attention to the chick, the van den Broek family works with 20 employees in the hatchery to deliver a quality chick.

Smart running lines with an eye for hygiene

The Afferden location was completely renovated in 2012. In consultation with Pluriton, the hatchery was rebuilt and redesigned with smart running lines and advanced equipment. Hygiene is paramount at Van den Broek. „We arranged the hatchery so that both on the side where the hatching eggs come in and on the side where the chicks are loaded there is a 'clean path,'” Jip van den Broek says. On both sides there is a cleaning area for cleaning and disinfecting, of the trucks. The hatchery has official approval as a cleaning and disinfection site for this indoor cleaning site to prevent the introduction and spread of animal diseases. With the set-up of the hatchery, it is possible to use labor efficiently and in a hygienic way, so we can never go from the clean to the „dirty” part.

Hygiene inside the hatchery

The clean area in the hatchery consists of the areas with incubators, hatchers, the inspection area, the inoculum storage area and the chick room. To get into the clean part of the hatchery, everyone has to go through the hygiene lock. That means showering, putting on work clothes and then going through a lock to disinfect footwear and hands. The hatching eggs enter the hatchery on pulp trays. Then the hatching eggs are selected by size and placed on plastic trays suitable for the pre-hatching process. To keep bacterial pressure low, hatching eggs are disinfected on the outside before the incubation process begins.

Constant temperature in incubator

The HatchTech incubators are set to keep the eggs in the 28 pre-incubators at a constant temperature of 100 degrees Fahrenheit (37.8 degrees Celsius) during the incubation process. „I deliberately choose to maintain a constant temperature during the pre-incubation process so that the chances of making mistakes are minimal,” said the hatchery manager, who points out that multiple employees can set the incubators. This method, a constant temperature, does require proper planning of the timing of placing the hatching eggs in the pre-incubator. On average, the process of pre-breeding takes 18 days, but it can vary by several hours for each breed. All hatching eggs are in the hatchers for 3 days after candling, where the temperature is cooled back to remain at 100 degrees Fahrenheit.

Chicks’ Room

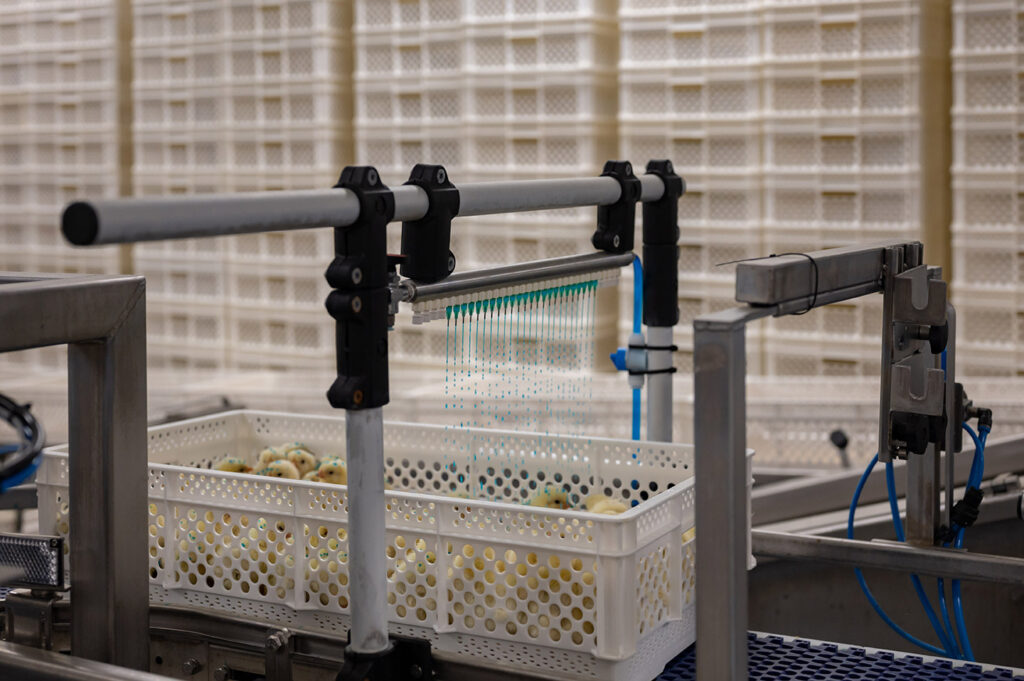

After hatching, chicks are processed in the chick room with optimal conditions for humans and animals. Thus, the health of the employees at the hatchery is also considered. The dust and down released during hatching is vacuumed off the crates before the chicks enter the chick room. In the chick room, selection by sex takes place and chicks receive the ordered vaccinations.

Vaccination

„When designing the hatchery, we chose to store the vaccines far away from the chick room in a locked area. In this separate room we prepare the vaccines in a careful- and hygienic way,” Van den Broek said.

Making the vaccine for vaccinations is a meticulous job. For each vaccine, the procedure is different, depending on type of vaccine and how the vaccine is delivered, refrigerated or frozen. The buyer of the chicks determines which vaccination is needed, and depending on the type of vaccination, the chick receives it via needle, spray or drops. Hygiene is very important in this regard. Van den Broek takes no chances in this. Every day the needles and tubes of the vaccination equipment are replaced with new ones. Between vaccinations, needles and tubes are flushed with boiled and cooled bacteria-free water.

Cleaning

Hygiene is an important item that runs like a thread throughout the company. The walls are smooth and white and floors of all rooms are coated, making them easy to clean. Cleaning is therefore a daily chore in the hatchery. The crates where the chicks crawl out of the egg are also washed, cleaned and disinfected in a separate room at the hatchery. ” By working carefully and hygienically, we do our utmost to deliver a quality chick,” says hatchery manager Jip van den Broek who runs the family business with great passion.

"By working carefully and hygienically, we do our utmost to deliver a quality chicken."